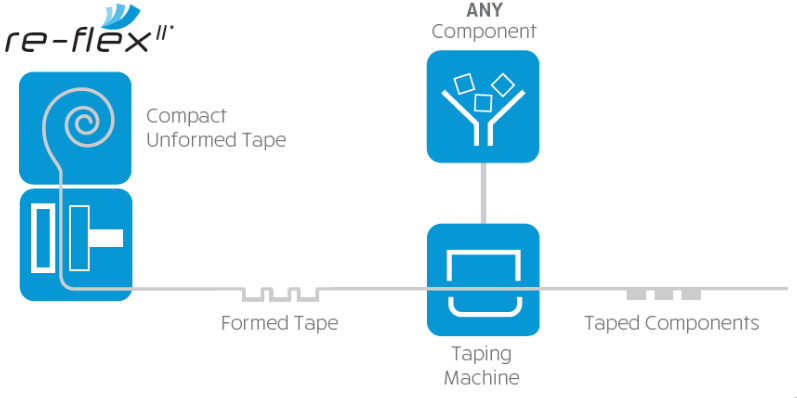

Rather than holding stock of a wide variety of reels of pre-formed tape, the Re-flexII system allows tape to be embossed as required, thereby simplifying the process, reducing cost and cutting the space required for storage. On-Demand Tape offers the perfect solution for component manufacturers, electronics assembly and kitting houses. Re-flexII uses smart, low-cost tooling to quickly and efficiently create any pocket shape – from basic to complex.

Both standard and custom tooling is available from Adaptsys, although the open approach of the Re-flexII also promotes tool design and manufacture by chosen local suppliers or in-house, minimising lead times and cost.

By integrating the production of tape into the manufacturing process, Re-flexII significantly improves process efficiency. In modern high-mix, low to mid-volume production environments, Re-flexII eliminates the problem of sourcing part reels of products by producing exactly the amount of tape required for the batch/job, thus increasing efficiency, reducing storage space and eliminating wastage with the revolutionary concept of “On-Demand Tape”.