Designed as a table-top machine with an optional stand is available, the TM 400 series offers a simple and compact automated taping system.

A 2D vision inspection system is used for over tape verification to ensure components are correctly oriented.

Set up is very simple, via a touch screen interface, minimising the time operators have to interact to ensure fast, dependable and accurate operations.

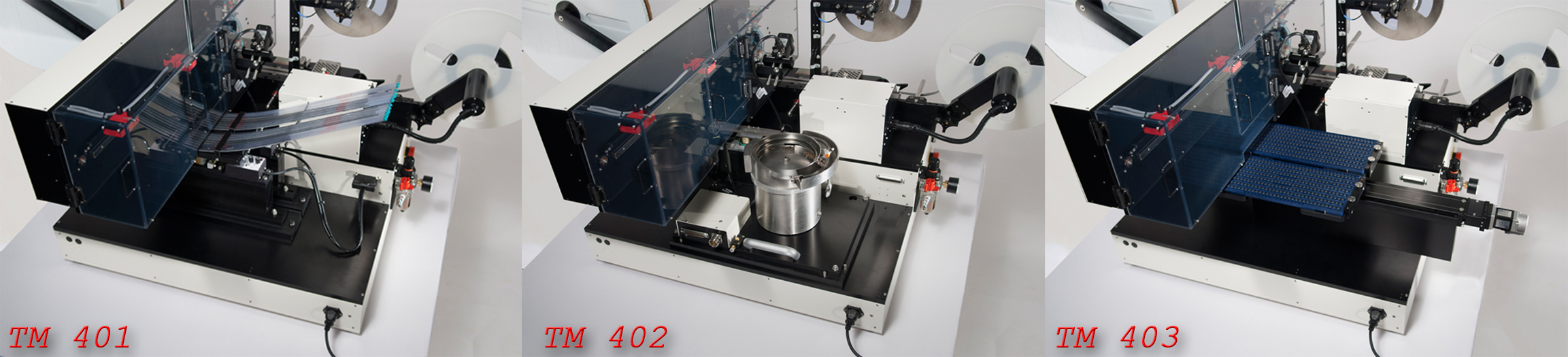

400 Series Models

Model variants include:

- TM-400 - OEM Version

- TM-401 - Tube Input

- TM-402 - Bowl Input

- TM-403 - Tray Input

Primary Features

- Touch screen operator interface

- Part rotation - +/- 90 or 180 degrees

- Universal heat seal or pressure seal cover tape

- Adjustable track width for carrier tapes with widths of 8mm to 72mm

- Jam in Track sensor

- Low Cover Tape sensor

- 2D Vision Inspection

Controls

- Touch Screen control

- User friendly setup

- Customisable job configuration

- Sealer dwell adjustment

- Password protection

- Manual/Auto Leader/Trailer

Specifications

Height: 100cm

Width: 135cm

Depth: 90cm

Weight: 98.5Kg

Power: 120VAC ~ 240VAC

Air: 5 SCFM at 85 PSI

UPH: 2000 to 3,500, device dependant